Research Team:

UNH College of Life Sciences and Agriculture: Easton White (project lead), Brittany Jellison (project lead), Bonnie Brown, Andrew Villeneuve

UNH College of Engineering and Physical Sciences: May-Win Thein

New Hampshire’s growing oyster aquaculture industry brings significant economic benefits to the state, but farmers’ success is heavily dependent on properly choosing a site and monitoring water quality conditions at that site. A current limitation, however, is determining the suitability of a site and oyster health as environmental conditions change throughout a season and across seasons. As such, developing, testing and implementing a network of oyster-attached biosensors at farms located in New Hampshire Great Bay can significantly improve oyster farmers’ ability to succeed.

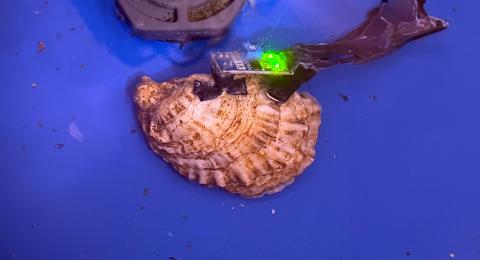

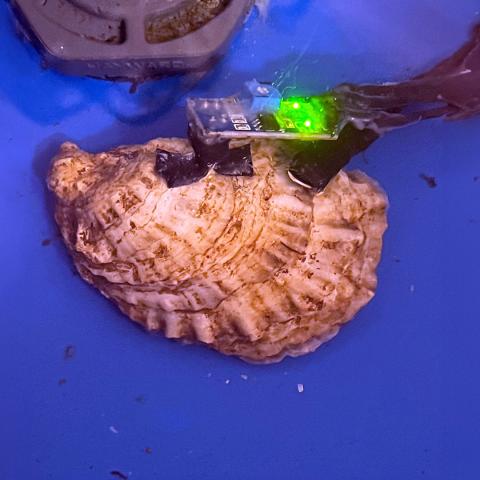

Top row, LtoR/TtoB: An oyster with a biosensor attached; marine biology master's student Michaela Edwards '23 attaches sensors to oysters; a tank with oysters and attached sensors being tested; summer lab interns Peyton Lockett (from Jackson State University) and Julia Bolton (University of Vermont) test sensors attached to oysters.

According to Easton White, an assistant professor of biological sciences at the UNH College of Life Sciences and Agriculture, oyster farmers may have little to no growth in their stock each season—or they might even see decreases in their oyster numbers due to high mortality rates. Often, this will leave producers questioning what caused the mortalities and/or diminished stock growth.

“Oyster farmers and resource managers require real-time data to make decisions and understand what factors may be affecting their oysters,” said Easton. “With this information, farmers could increase revenue by boosting oyster growth rates or reducing mortality.”

The research is being carried out in three main phases. First, a network of biosensors is being built and tested in collaboration with a joint undergraduate engineering and biology course (TECH 797) at UNH, with co-instructors Elizabeth Fairchild, a Station scientist and a UNH research associate professor of biological sciences, and May-Win Thein, an associate professor mechanical and ocean engineering in the UNH College of Engineering and Physical Sciences. The biosensors use high-frequency non-invasive technology—involving small high-frequency electrodes attached to the oyster valves—to monitor the distance between the tips of the upper and lower jaws, or gape distance, as a proxy for health. Data from these sensors will be transmitted and analyzed at UNH.

Additionally, lab experiments are currently being conducted at UNH’s Jackson Estuarine Laboratory and the Coastal Marine Laboratory to identify baseline and stress response signals in the biosensor information. Oysters are being subjected to controlled stress scenarios—such as low pH levels, high temperatures, and invasive predators—to observe their responses. Using the biosensors, the research team is identifying thresholds for different health outcomes in the oysters under stress.

“With these sensors, farmers can see what is hidden under the surface, receiving a real-time look at changes in the activity and behavior of farmed oysters and helping them determine practices that can improve the health of their stock and the sustainability of Great Bay’s burgeoning oyster industry.” ~ Brittany Jellison, an assistant professor of biological sciences, COLSA

According to Bonnie Brown, Station scientist and UNH professor of biological sciences, “As the sensor network monitors environmental data and gaping activity, it turns the aquacultured oysters into ‘oyster sentinels,’ providing farmers an alert on issues like feeding, winter torpor, water quality, hypoxia (low oxygen conditions) and thermal changes.”

“It’s a tiny little bit of mechanization with a potentially big punch for New Hampshire and regional aquaculturists,” Brown added.

The biosensor system will be deployed at two oyster farms in Great Bay. The farmers will receive real-time data and interpretations of the data, known as "health check-ins," which will help them make more informed decisions about their oyster farming practices. The system will also be equipped with additional sensors to monitor temperature, light, dissolved oxygen and pH—all of which are important aspects of oyster habitat.

Deployment of the sensor network will empower aquaculture farmers to identify influential environmental factors that impact changes in oyster condition, further enhancing the industry's productivity while ensuring food safety standards. This, in turn, can lead to higher revenue for oyster farmers and contribute to the overall economic growth of the state.

This material is based on work supported by the NH Agricultural Experiment Station through joint funding from the USDA National Institute of Food and Agriculture (under Hatch award number 7004025) and the state of New Hampshire.

Brittany Jellison, Assistant Professor of Biological Sciences (project lead)

Contact:

Brittany.Jellison@unh.edu, Marine Ecophysiology Lab

Bonnie Brown, Professor of Biological Sciences

Contact:

Bonnie.Brown@unh.edu, Ecological Genetics Lab

May-Win Thein, Associate Professor of Mechanical and Ocean Engineering

Contact:

May-Win.Thein@unh.edu

Andrew Villeneuve, Ph.D. student, Marine Biology

Contact:

Drew.Villeneuve@unh.edu, website